Dizzing the Night Away

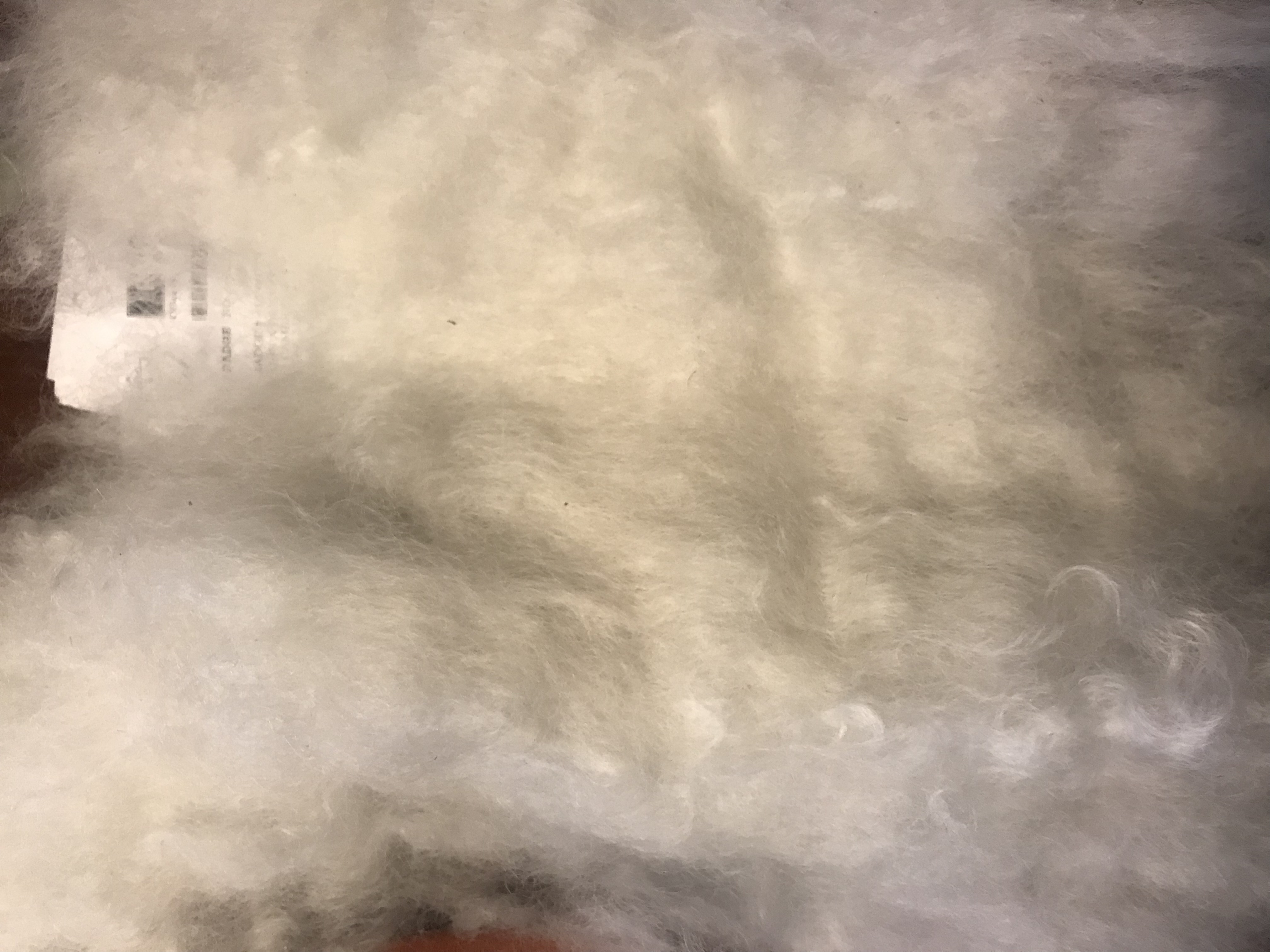

While one can spin directly from a carded batt, it’s easier to spin if it’s in “roving” form, which is a very loose strand of mostly-aligned fibers.

This transformation is accomplished using a “diz”, and I have no notion of that word’s etymology. Or entomology, for that matter. A diz is just something with a hole through it. Mine is a piece of wood:

A bit of fleece from the batt is pulled through the hole, and the fiber is pulled out one side while being stretched out, or drafted, to make it fit through the hole. Simple, really.

(Oh, and that bit of paper in the bag is a processing tag. It’s a bit of a Tyvek envelope with the fiber and (hopefully) the sheep’s name, written in Sharpie. One tag goes into each wash bag so I can track which is which, as I often process multiple fleeces.)