I’ve recently entered into an agreement with a yarn shop in Western Massachusetts to sell my yarn. For the past few months I have been spinning, and spinning, and spinning. Now that I have sufficient inventory, it’s time to dye some of the yarn for sale. Plain white yarn can be rather boring.

I’ve dyed yarn before, but never with an eye toward reproducing the color I wanted, so I read up on the subject (internet, of course, but Gail Callahan’s book Hand Dyeing Yarn and Fleece is a great resource). From several sources I encountered the underlying theme of “1% dye stock”, which harkens back to chemistry classes of the past. A 1% dye stock, matched gram-for-gram with the “weight of goods”, provides a “medium” shade of the color, whatever that means. (It turns out that a “medium” shade is just about perfect.)

Peggy selected four colors of dye for the Spring Line – in the picture above, from left to right are “Duckling”, “Ballerina Pink”, “Hyacinth”, and “Sea Spray”. All dyes were from Dharma Trading. For a 1% dye stock, I weighed out 20 grams of each dye powder into a cup, and added a squirt of very hot water to mix that evenly into a paste, to make sure that it’s all dissolved. That paste got diluted into enough water to yield 2,000 ml (2 liters) of dye stock.

I used vinegar as a mordant again. A mordant is a chemical that helps the dye absorb into the yarn. As these are “acid dyes”, an acid mordant is the right choice. I could have also used citric acid crystals, which I also stock, but that’s more expensive than vinegar.

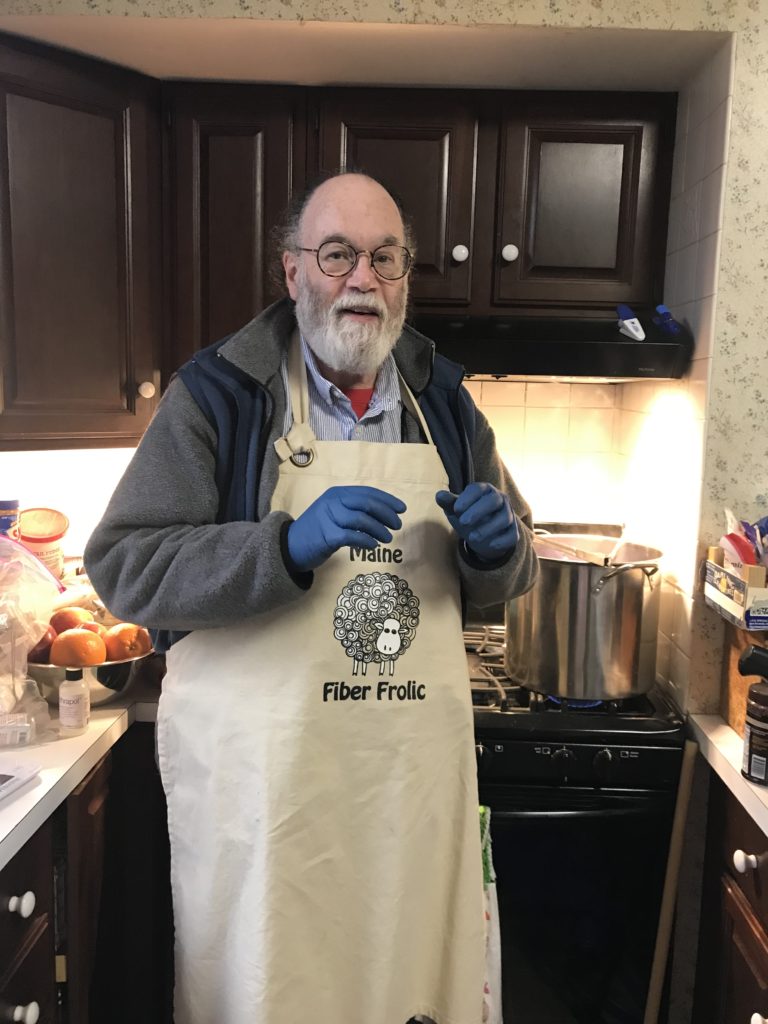

After the dye stocks were made, it was time to dye. For each of the colors, I pulled three skeins of yarn from stock and weighed them. It’s important, for reproducing a color again, to know how much dye and how much wool was in the mix. This time around I’m even writing a dyeing journal so I can remember what the mixes and ratios are.

The weights and dyes I used were:

360 ml of Sea Spray for 358 grams of yarn

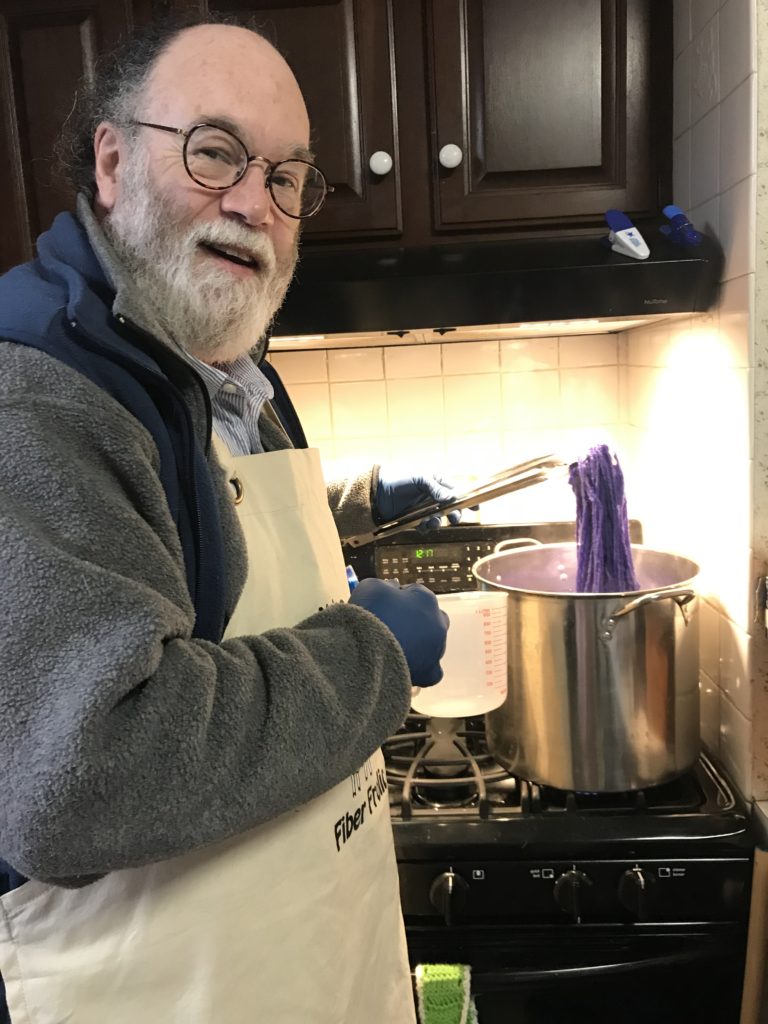

390 ml of Hyacinth for 388 grams of yarn

390 ml of Ballerina Pink for 388 grams of yarn

510 ml of Duckling for 504 grams of yarn

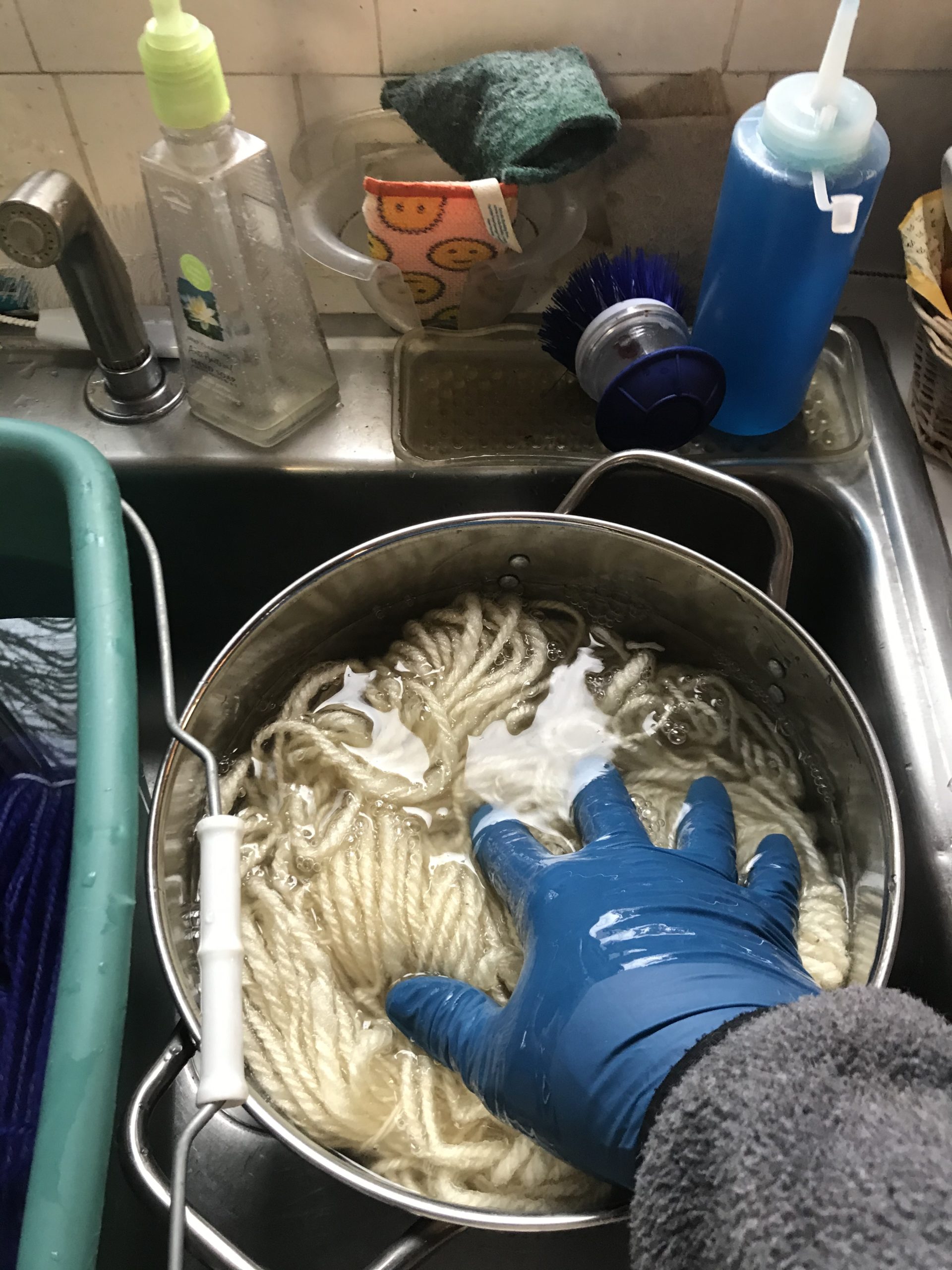

After weighing the yarn, it is soaked in a 25% vinegar-in-water solution, which is about 1.5% acetic acid. The soaking step opens the fiber up to accept the dye and also eliminates air bubbles in the yarn that would prevent the dye from getting to the yarn. Artistic effects can be added by controlling how well-soaked the yarn is, with dye penetrating better in some areas.

Tongs are used to gently move the yarn around in the dye, and keep the yarn from sitting at the bottom of the dye pot. Notice the Tyvek labels to identify the yarn and list the yardage.

After the yarn is dyed and drained, it’s twice rinsed in clear water to remove the vinegar, then hung to dry.

After the skeins are dry, I’ll rewind them into nice skeins, attach labels, and package them for shipping to the yarn store.

Postscript:

I believe I’ve discovered another of those “don’t do this” issues as well. The yarn in duckling had just been plied and skeined, not washed. The thee skeins in duckling were uneven in color take up. I believe it’s because the yarn wasn’t clean enough. Live and learn.

Leave a Reply

You must be logged in to post a comment.