Yes Sir, Yes Sir, Three (er, Four) Bags Full

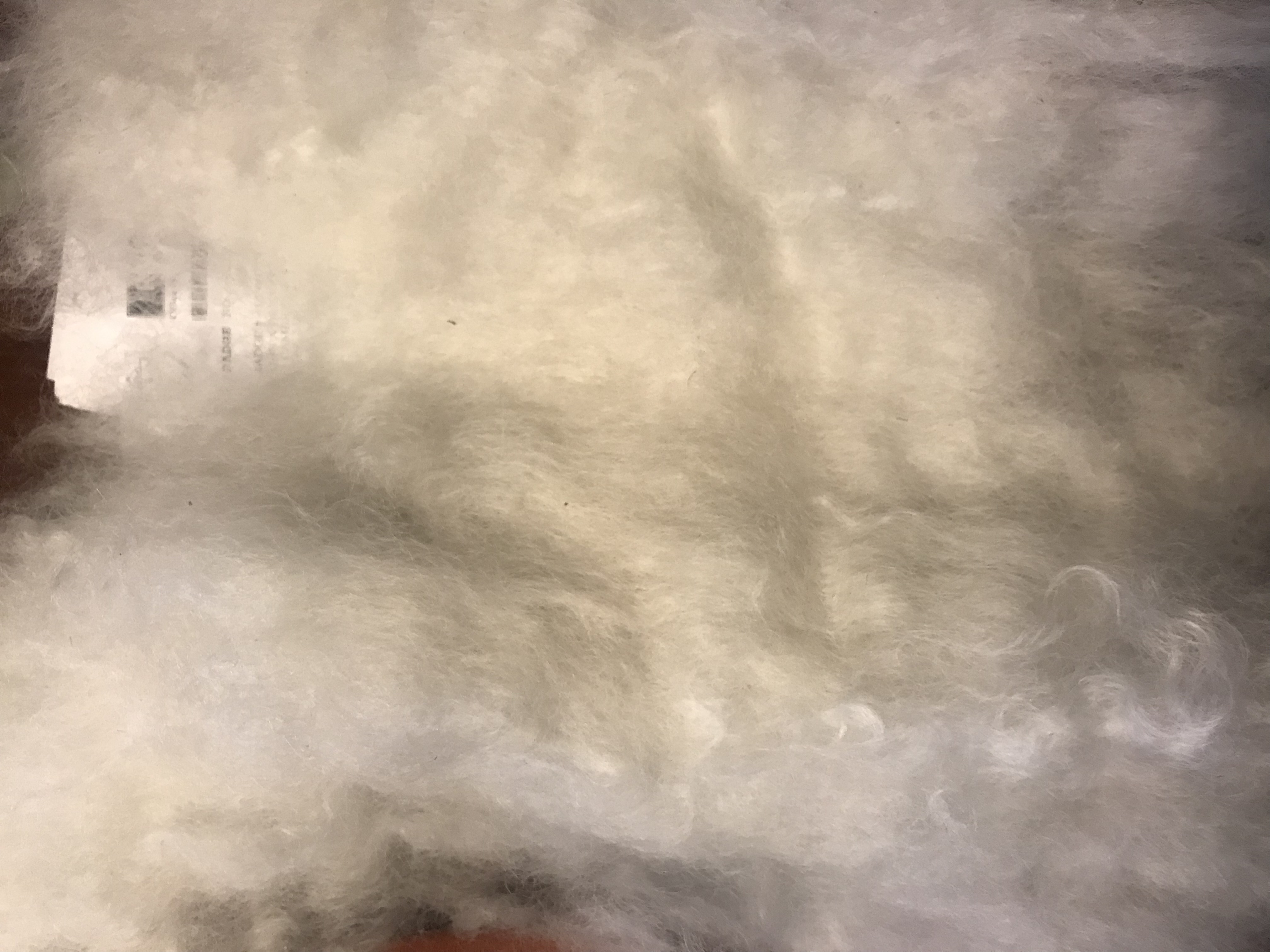

I just returned from a day trip to Waldoboro, Maine, to retrieve some 16 1/2 pounds of roving I had professionally processed into roving. Four large bags were waiting for me. This is the result of 19-odd pounds of fleece from three Romney sheep. I apologize for not knowing their names.

I had purchased the fleece from farmers who raised the sheep for their handspinners-quality fiber. I then cleaned them to remove as much of the leftover crud as I could find (not all, as it turns out…) and bagged them loosely for the trip north or processing. I was headed to Fiber Frolic and arranged to drop off the bags there.

Nancy at New AIM Fiber Mill washed and picked it, then carded it to roving, all ready to spin.

For those of you that are number people, 19.2# of dirty fleece washed out to 16.9# of roving so there was but 2.3# of waste, including dirt, sheep sweat, lanolin, and (some) of the bits of hay and bedding I missed. But this roving is just beautiful!

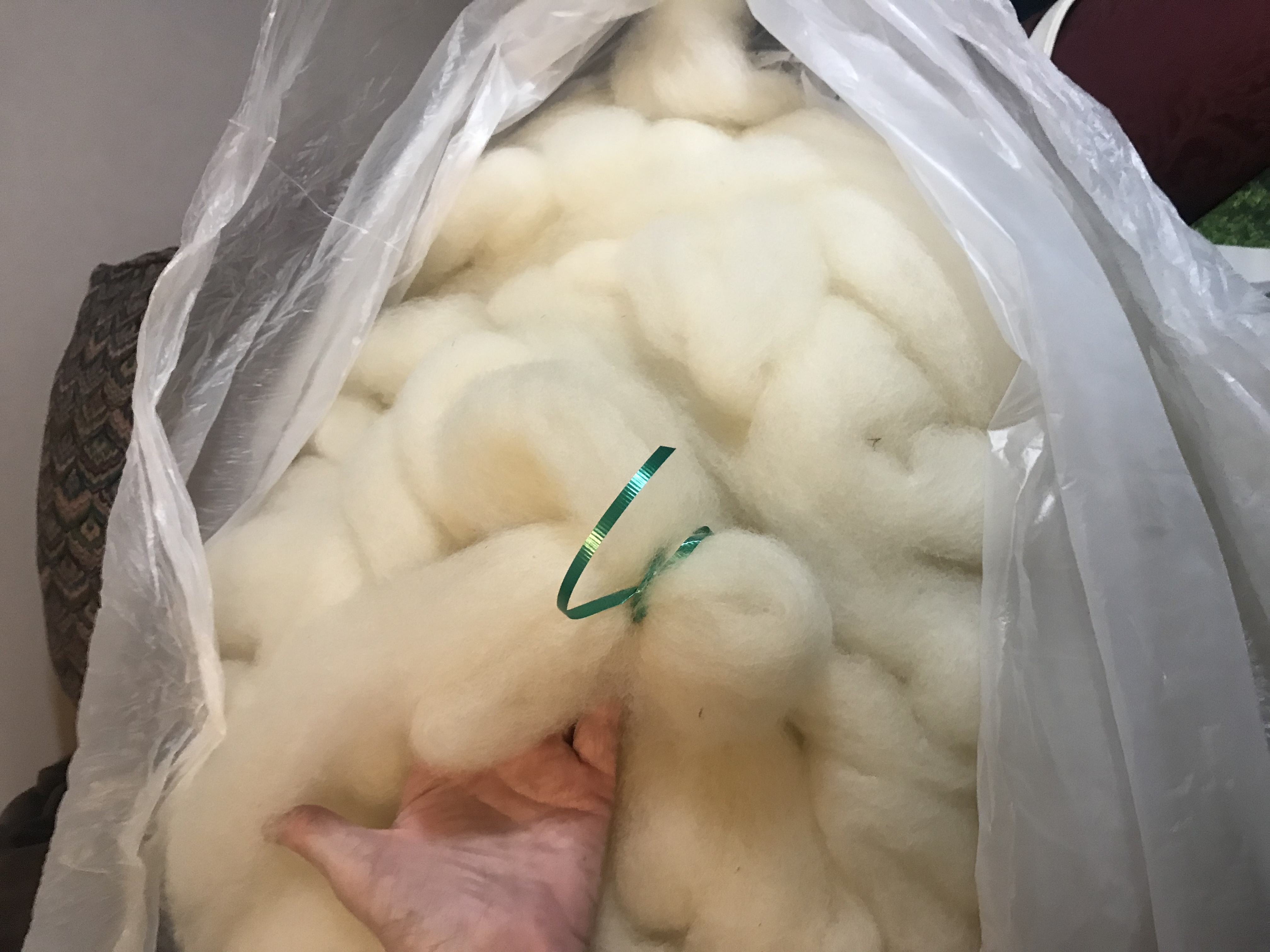

The ribbon makes it easier to find the end…